Background

Production Co-Pilot

AI & Machine Learning are technologies that previously have been difficult to use in a manufacturing environment. The Tricloud Nexus platform enables that, and it opens up a new world of opportunities in the manufacturing environment.

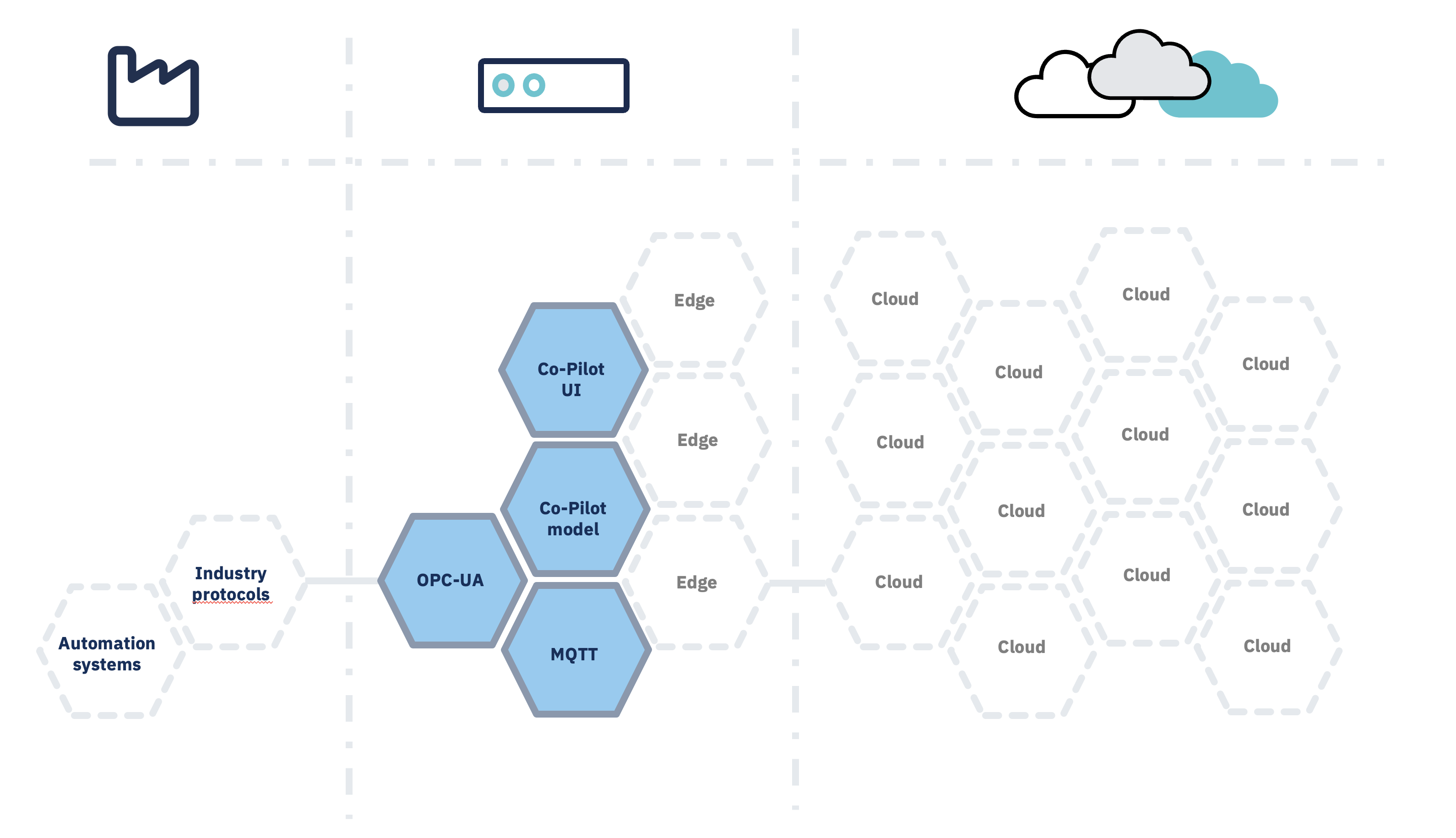

The Tricloud Nexus platform collects data from the processes, stores data in a unified structure in cloud, and thereby leverages new state of the art analytic tools, making it possible to generate a ML-model that can be downloaded to the factory floor.

The Tricloud Nexus Co-pilot application, will help and guide the operator towards optimal performance, by continuously predicting production performance based on current production setup.

Summary

Challenges

Manufacturing and production machinery setups are increasingly getting more and more complicated to operate. The individual machines contain an ever increasing number of parameters that can be adjusted to the need of the manufacturing process. Changes in environment and many product variants can in some cases complicate things even further. Interactions between machines on a production line can also be a factor.

All this complexity is to be handled by the production operators, and it can be quite difficult to find the optimal setup in any given situation.

Approach

Using Tricloud Nexus built-in analysis, visualization and improvement tools enables the development of an AI model, which over time will learn the optimal adjustments of how to run the production process. You can harness this to train a production Co-pilot that in real-time is able to predict how different adjustments to process will impact productivity and quality of the product.

By using Tricloud Nexus you will be able to have a Production Co-pilot that can assist the operators on the factory floor in maximizing performance and quality output on a continuous basis. The Co-Pilot will be setup for continuous learning, and will continuously adapt to changes in the production environment.

Benefits

The immediate benefits are obvious. By using the Production Co-Pilot, most mis-adjustments during productions runs can be eliminated and productivity and quality can be improved. At the same time, onboarding of new production operators becomes easier and faster. The Production Co-Pilot also enables utilization of best practices between shifts.

Reference architechture