Background

Easily deploy OEE information to all production units, and other relevant stakeholders

In smart manufacturing, obtaining automated Overall Equipment Effectiveness (OEE) marks the initial step toward digitalization. OEE offers valuable insights into the operational efficiency of machines by assessing three key metrics:

- Availability – Measures the accessibility of the machine during scheduled operating times

- Quality – Evaluates the percentage of products manufactured without defects

- Performance – Compares the actual production speed of the machine to its optimal speed

The performance of the machine is directly correlated with its numerical rating, indicating its efficacy within the factory setting. This rating offers a comprehensive insight into potential issues, enhances understanding of machine functionality, and serves as a foundational tool for identifying and addressing any challenges the company may encounter.

Summary

Challenges

If you haven't previously measured your OEE, you may unknowingly spend valuable time operating machines at suboptimal speeds due to undetected errors. Without a numerical gauge of machinery performance, you miss out on a significant opportunity to proactively optimize your workflow.

Conducting the OEE process manually requires checking OEE numbers for each machine individually, resulting in wasted time and manpower on a task that could be easily automated for greater efficiency.

This is where Tricloud Nexus can help you get valuable insights.

Approach

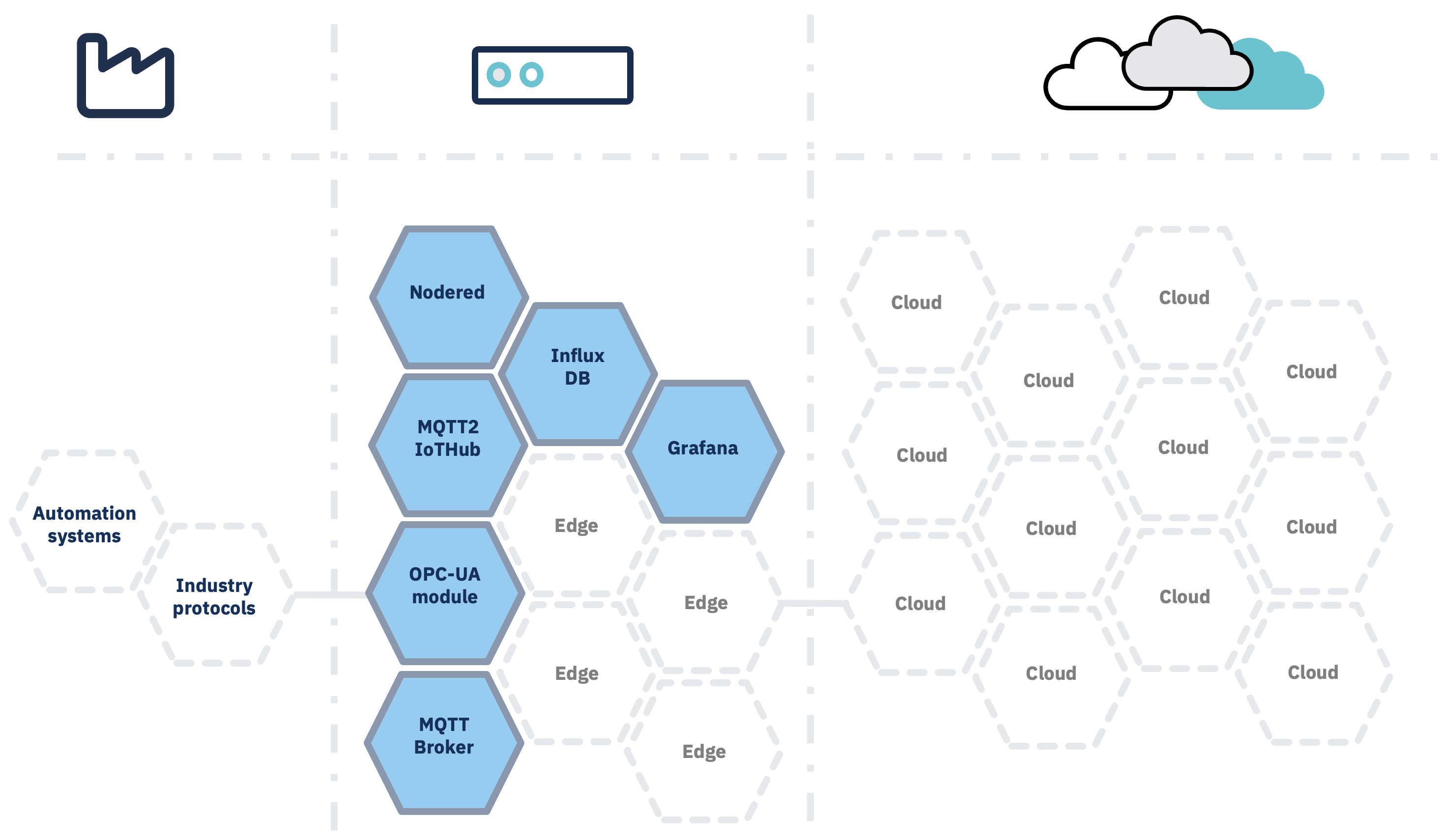

Using Tricloud Nexus you gain access to an automated OEE process. The platform offers seamless deployment of the OEE application directly onto the production floor and all necessary tools for data collection and visualization are readily available.

The OEE application efficiently collects and computes data from all company machines, providing insights into the availability, quality, and performance of individual machines, specific production lines, and the entire factory. Visualization tools offer a clear overview of machine performance, allowing you to monitor operations and identify any deviations from expected reliability levels.

The application enables you to closely track machine performance and compare it against expectations or historical data. Any significant drops or consistently low numbers indicate potential issues, prompting immediate action and corrective measures.

With Tricloud Nexus, proactive maintenance becomes effortless, ensuring smooth operations and minimizing disruptions to your production processes.

Benefits

Automated insights into your machine operations allows you to maintain focus on productivity, quality, and performance. Equipped with accurate and reliable data, your company gains greater confidence in decision-making processes.

Valuable time and money are saved, by promptly detecting and addressing errors from machinery and flawed products. Additionally, with insights into machine productivity, you can efficiently optimize operations.

The OEE application features a simplified setup, consolidating all necessary tools into a single deployment that seamlessly integrates with any system. It's user-friendly, accessible, and provides a clear and comprehensive overview of your operations.

Reference Architecture