Background

Computer Vision

Visual inspection on produced goods is essential in almost any industry. Combining computer vision and AI technologies makes you able to automate your quality control processes, and at the same time collect valuable data to the Cloud about the quality of your produced products. This data can be used to further optimize your processes.

A computer vision system never gets tired. With the Tricloud Nexus platform, you can integrate your quality data into your reporting requirements, streamlining your operations and enhancing efficiency.

Summary

Challenges

The system is confined to specific sites and lacks online connectivity. Consequently, addressing system errors or implementing updates necessitates manual visits to each site and device.

This manual intervention proves to be time-consuming, inefficient, and costly.

Additionally, you've noticed that the camera fails to detect all flaws, and without cloud connectivity, accessing older data to refine the algorithm becomes cumbersome. As a result, whenever an upgraded model is developed, a software engineer must physically deploy it across all sites. This process, once again, consumes valuable time and disrupts your optimization efforts.

This is where Tricloud Nexus steps in to offer a solution.

Approach

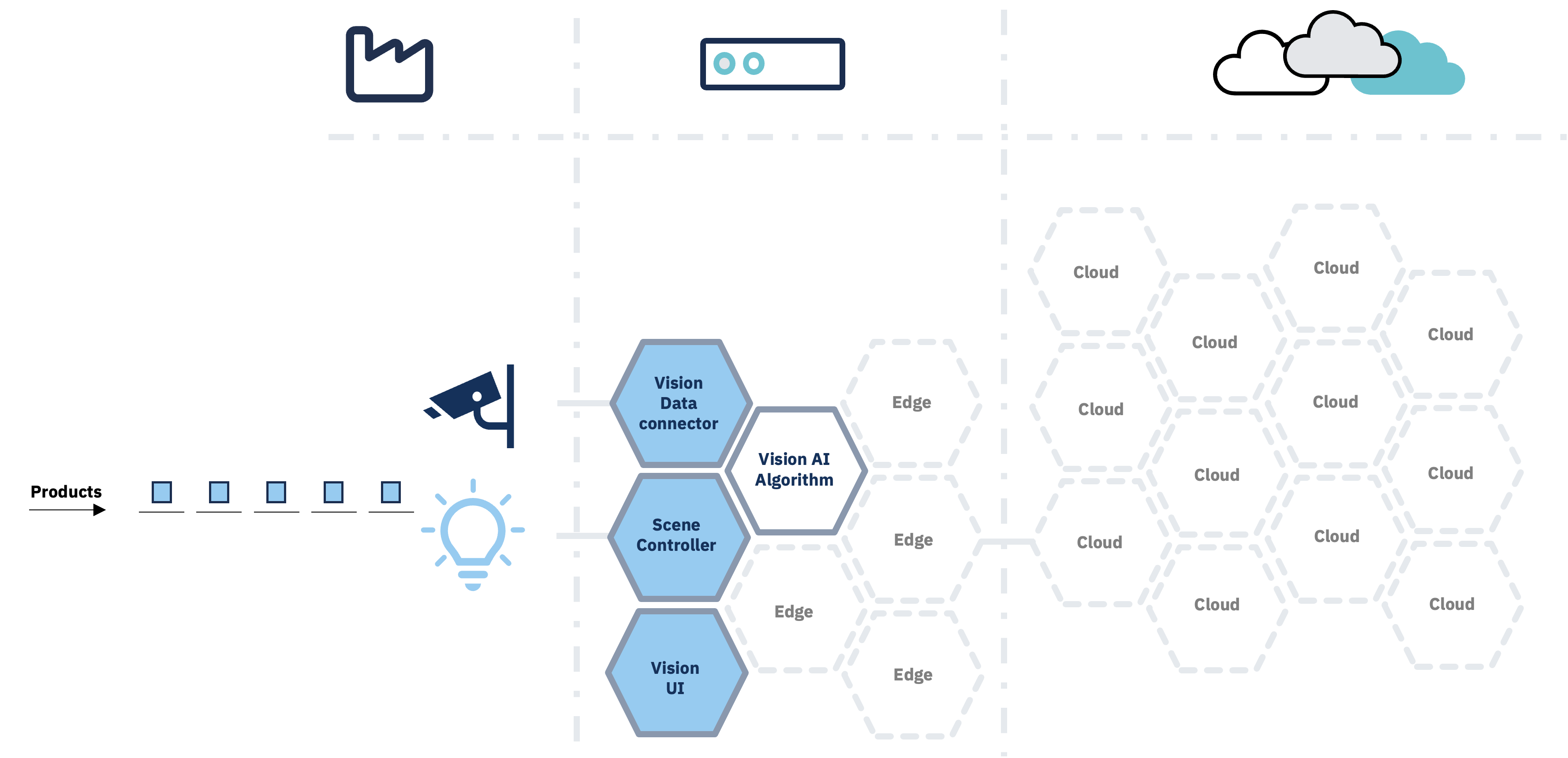

Our platform seamlessly enabled the implementation of Computer Vision solutions. By connecting a camera to the edge device, it efficiently executes flaw-detection and other detection algorithms along the product line. This capability is made possible through our modular platform design, allowing easy integration with any system utilized on your site through the configuration of requisite protocols.

Modelling Computer Vision follow the ML Ops cycle, beginning with model development from collected data, followed by packaging in the container registry. Prior to deployment across one or many devices, the model undergoes validation through rigorous testing. Subsequent monitoring and analysis is conducted to assess the performance of the new model.

Leveraging the Tricloud Nexus for packaging and deployment, seamlessly integrated with your Azure Cloud subscription, this process can be executed repeatedly and swiftly, even multiple times per day if required.

Central to this process is traceability, allowing you to meticulously track and analyze the performance of your deployed models.

Benefits

Taking advantage of Tricloud Nexus Computer Vision capabilities result in significant time and cost savings. Our automated processes enable remote deployment, configuration, and monitoring, while offering roll-back capabilities in the event of an error in the model.

By continuously updating the model, your company can effectively identify product errors, ensuring enhanced product quality and competitiveness in the market.

Our platform accelerates your company's optimization efforts by providing comprehensive traceability throughout the iterative process of model training. This seamless integration allows for repeated cycles of optimization, effortlessly enhancing efficiency.

With Tricloud Nexus you are sent onto a development fast-track.

Reference architechture