Industrial IoT -> A foundational step towards Industry 4.0

Industrial Internet of Things (IIoT) is a concept that creates the possibility to connect technical installations to the cloud, and thereby unlock multiple business opportunities.

The Tricloud Nexus platform supports digital convergence between traditional cloud-based IT solutions and computer systems placed either on the factory floor, in various products, or global supply chains.

By installing an Industrial IoT platform as part of your company’s overall IT solution, you set the foundation and unlock the possibility to utilize the many advantages promised by Industry 4.0. Without a strong foundation, like Tricloud Nexus, you risk losing momentum on your digitalization journey.

But first let us get an overview of the fundamental concepts when working with Industrial IoT.

Industrial IoT Domains

In the context of Industry 4.0, smart manufacturing involves connecting various machines, devices, and systems across a manufacturing facility through internet technologies. This connectivity allows for seamless communication and data exchange, leading to more automated and efficient manufacturing processes.

When integrating IIoT with smart manufacturing you can achieve real-time data analysis, predictive maintenance, and optimized resource management.

This comprehensive insight can result in enhanced productivity, reduced operational costs, and improved decision-making.

IIoT is a key enabler in transforming traditional factories into smart, interconnected environments.

Connected products in the IIoT context refers to manufactured items embedded with sensors, software, and connectivity features. These products can communicate and exchange data with other devices and systems over the internet.

In an IIoT setting, this connectivity allows for enhanced product tracking, real-time data monitoring, and remote control or optimization. It provides valuable insight into usage patterns, performance, and maintenance needs, so you can improve the product, predict maintenance, and customize the service.

Connected products exemplify the integration of physical goods with digital capabilities, leading to smarter, more interactive, and valuable product offerings improving your product after you have shipped it to the customer.

In the context of IIoT, smart supply chains utilize advanced technologies such as IoT sensors, AI, and data analytics to optimize and automate supply chain processes.

This integration allows for real-time tracking of goods, predictive analysis for demand and inventory management, and enhanced coordination between different parts of the supply chain.

Smart supply chains that utilize the IIoT technologies are characterized by their increased efficiency, transparency, and responsiveness. They can adapt quickly to changes in demand or supply conditions, reduce waste and delays, and improve overall supply chain performance.

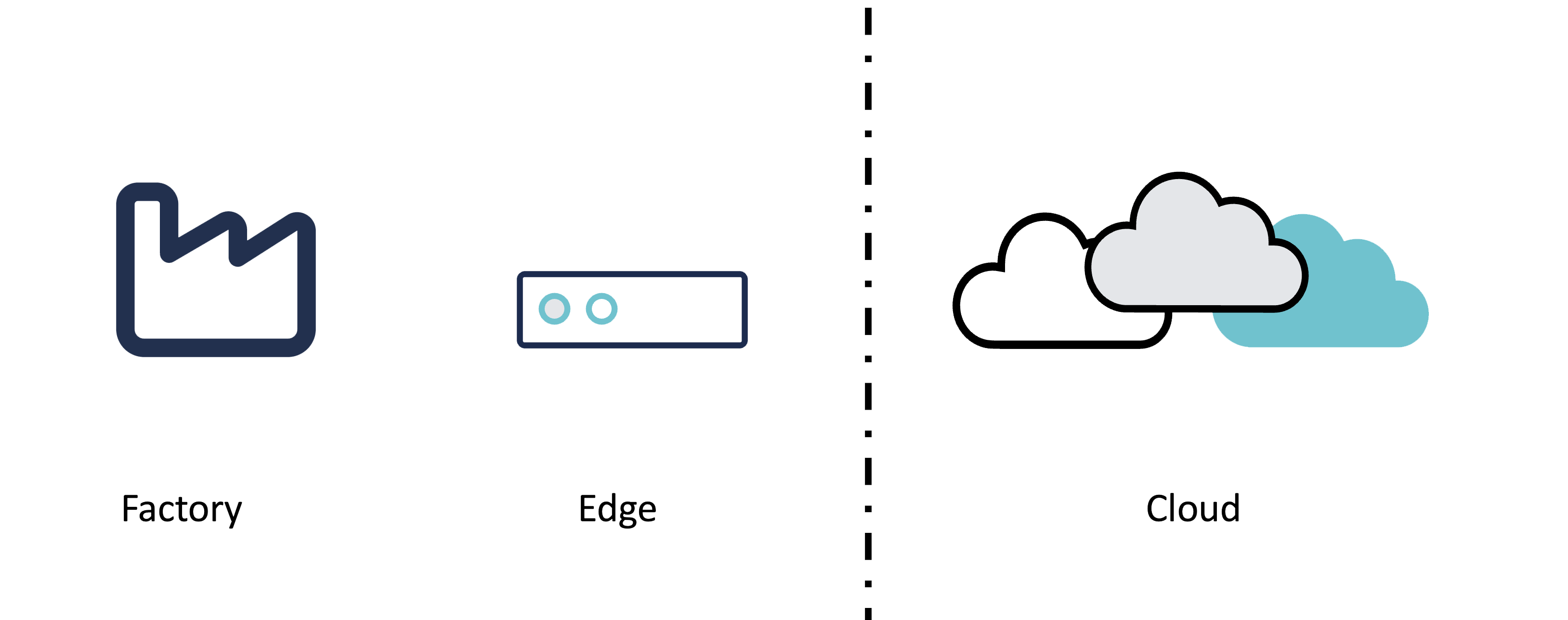

Industrial IoT Framework

Types of edge devices

IoT device

IoT device based on a microcontroller architecture

This type of edge device is built around a microcontroller, a small, low-power computer on a single integrated circuit.

It typically handles specific, simple tasks like collecting sensor data, basic processing, and sending this data to a more powerful system for further analysis.

These devices are compact, energy-efficient, and ideal for straightforward, repetitive tasks in an IIoT environment.

Edge device

Edge device as a separate computer or virtual machine

This edge device operates either as a standalone computer or as a virtual machine (VM).

It is more powerful than microcontroller-based devices and more capable of performing complex processing and analysis of data locally. As a separate computer, it has dedicated hardware resources, while as a VM, it shares physical hardware with other VMs, offering flexibility and efficient resource utilization.

These devices can handle more demanding tasks like advanced analytics and real-time decision-making.

Edge cluster

Edge cluster running in a highly available and fault tolerant Kubernetes cluster

A cluster in this context refers to a group of nodes capable of running multiple instances of your modules managed by Kubernetes.

Kubernetes is an open-source platform for automating deployment and scaling. Operations of application containers enables applications with high availability and fault tolerance.

This setup ensures continuous operation even if some modules fail, making it robust for critical IIoT applications, where downtime is not acceptable. The cluster approach allows for scalable and resilient edge computing capabilities in an IIoT environment.